Want to measure the uniformity of concrete mix? Well, then there is one simple way available that is the slump test. This test is basically performed to determine the workableness of concrete mix whether it is up to the mark or not.

Instruments Needed For This Test:

• Slump Cone

• Tamping Rod

• Spatula

• Brush

Slump Test Method:

- First of all, clean the cone with the help of a brush or some water. Make sure that the cone is not wet or completely dry as it may result in changing mixed water content.

- Then, the cone is properly positioned on a durable surface and it is compulsory to take hold of the cone firmly by the operator.

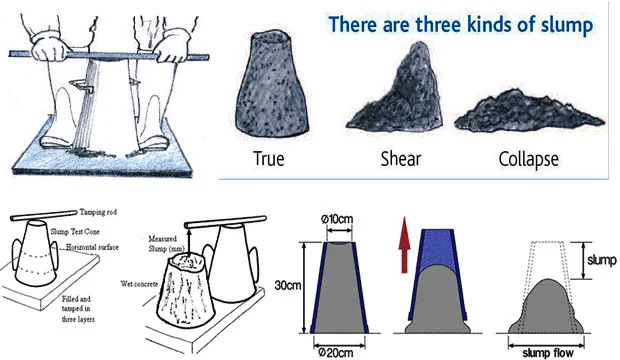

- The next step that comes after is concrete pouring. Using three layers and keeping all but the same height concrete is poured. All layers should be compressed 25 times with the use of the tamping rod.

- When the cone is full to the edge, needless concrete is removed with a spatula.

- After all the aforesaid steps cone is then lifted up mildly with proper care, if ignored then tilting can result in altering the slump.

Measurement:

Slump is then calculated quickly by calculating the variation between original cone height and specimen height.

Slump Categorization:

Slump test not only signifies workability but other mixed properties such as segregation resistance, cohesiveness also.

Slump can be categorized into a true slump, shear slump, or collapsed slump based on shapes.

In case of break down or shear, the slump is obtained then the test is recapped to make certain that results are ideal. Collapsed slump points out that mix is too wet or it is high applicability mix as a prerequisite against self-compacting concrete. For this particular reason, this test is worthless. So, other tests like flow test, V-funnel test, or J-ring test are recommended for high workability mix as well.