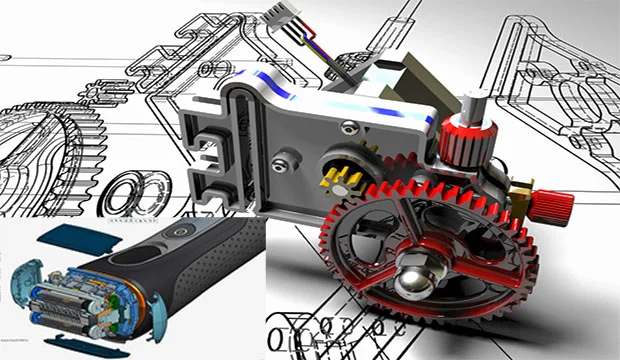

2D Drafting is an important part in the mechanical and engineering designs for manufacturing process since more than two decades. They have successfully provided Major and specific information on the endurances and dimensions needed for it and functionality of a part for product manufacturers. However; the harsh truth is that with arrival of software and technological tools like SolidWorks, Inventor and many more tools similar to that, mechanical 2D CAD drafting is unable to keep up in tune with the design and manufacturing industry, nowadays.

In comparison with 2D drafting approach, 3D approach in mechanical design and manufacturing allow organizational users to save time and cost simultaneously.

Monitoring of single geometric file is a facility

In order to get the description of a complex 3D object with harder schedules and increasing pressure for well-organized and exact designs 2D CAD drawings is not an impressive way at all. Unquestionably it will produce misconceptions of the design in the downstream procedure. This could also result to more impediments for the product development method.

On the contrary, this will not occur with 3D CAD design and 3D solid modeling as they clearly transmit and classify the 3D part in a single geometric file.

Accuracy and Plans

2D drawings are powerful enough to provide endurances and list of parts that are useful for manufacturing procedure. But approach of CATIA 3D Master allows product designers to make their drawings much easier to identify and evaluate because the drawings will not be on top of each other.

All designs & drawings are in sync

One more challenge that the product designers are facing is the syncing problem. Whenever they made any changes in their drawings, the whole sequence tends to fall out of sync. As a consequence, many product manufacturers faced the postponement in the development procedure.

On the other hand, the project manufacturers who use 3D approach in the product manufacturing design and development in the long run enhances the efficiency of the procedure and guarantees design changes are made timely.

Maybe these are the reasons that 3D approach has made its impression alongside 2D CAD drawings in the product manufacturing design and development industry.